Exploring the Manufacturing: Faucet Production in China

The global faucet market is expected to skyrocket at a CAGR of six percent between 2022 to 2027. This is because many consumers are demanding modernized faucet products for home improvements. It has made various faucet manufacturers focus on producing advanced products that meet quality control measures to suit this demand.

China faucet manufacturing has adopted technology in production to create innovative faucets and other sanitary ware. This has made many faucet manufacturers in China scale the ranks as top brands for kitchen and bathroom faucets. It’s become a hub for tap and sanitary ware production, with many factories emerging in different parts of the region to provide the best faucet products money can buy.

In this article, we explore the China faucet industry and some of the best manufacturers to partner with regarding sanitary ware. But first, let’s explore the current statistics for China’s faucet manufacturers.

Numbers Don’t Lie: Analysis of China Faucet Manufacturing Industry

China’s faucet manufacturing industry is experiencing massive growth, driven by urbanization and increased demand for high-end faucet products in the global market. Despite international competition, the domestic faucet industry has become the world’s leading supplier of affordable, innovative brass faucets.

With at least 1500 enterprises in popular faucet production regions like Taizhou, Zhejiang, Kaiping City, Guangdong Province, Changhua, Taiwan, Nan’an, and Fujian, among others, China has made an annual output of 10 billion Yuan.

More than that, it exported faucet products to a volume of 20%, ensuring both the domestic and international scale of production that been overly improved. Most regional bathroom faucet factories produce innovative mid-end products in many styles to meet customers’ needs. However, the industry has an acute vacancy for making luxury faucets.

Most international brands still dominate the Chinese luxury market as their customer favorites regarding high-end products. This poses an opportunity for the brass faucet industry in China, as they can start producing and marketing these new products to create a mark in the high-end market.

Let’s look at the differences between well-known international products and dealing with a China-based sanitary ware and faucet factory.

European Vs. China Sanitary Ware Manufacturers

While many European manufacturers have made their mark in producing quality products, China sanitary ware manufacturers have quickly become a go-to-go hub when customers desire quality yet affordable products. It has scaled up in innovation, using technology to improve its products to meet the demand for smart products.

Here are some reasons why many customers are dealing with faucet sanitary ware manufacturers head-on and eliminating the middleman.

Affordability

Quality sanitary wares are expensive, but this may just be what you need to complement and create that high-end, aesthetically pleasing home. Nonetheless, did you know there are manufacturing factories in China that can provide sanitary ware fixtures at low prices yet are of top-notch quality? Yes, you can deal directly with China manufacturers and eliminate the intermediary that increases costs.

Reliability

Since many faucet factories in China have been in the sanitary ware industry for a long time, they have a top-notch reputation regarding reliability than any upcoming faucet factory that’s just started. It’s, however, essential to conduct extensive research on each factory’s product before dealing with a particular brand.

If you have plumbing issues like leaks, you must work with a faucet factory that responds well to such grievances and queries. Nonetheless, such occurrences rarely happen since the manufacturing process meets quality control measures.

Product Quality

China manufactures pride itself in providing innovative products in different styles and designs of top-notch quality. Most sanitary ware manufacturing factories test their products before sending them to the market. Various testing processes include water and air testing to ensure their no leaks. Moreover, the products will also pass the NSS certification and other environmental regulations.

Creative Styles and Designs

Many factories in China are creating eye-catching product lines that meet the demand for modernized sanitary ware. Customers are looking for new innovative designs and styles that complement their home aesthetics to make it welcoming. The best route is a professional manufacturer, as you’ll have various options—you’ll be spoilt for choice. Moreover, you can choose from multiple finishes—like brushed Nickel, Stainless steel, or Matte black.

Dealing with a Chinese faucet factory eliminates issues associated with intermediaries and complications of finding quality products and a faucet manufacturer. Now, let’s get straight into the types of manufacturing companies you can partner with, depending on your needs and services.

Types of Faucet Manufacturers in China

When trying to partner with a Chinese faucet factory, you’ll need to find the right manufacturer that will cater to your needs accordingly. Here are the four main types of faucet manufacturers.

Original Design Manufactures (ODM)

The Original Design Manufacturers provide the plan and ensure they have strategic measures to execute it. The types of manufacturers are quite popular in China. If you’re trying to get the least volume of quality faucets and require an MOQ of about 500-1000pcs, then you can partner with Original Design Manufacturer (ODM).

Here are some benefits of working with ODM:

- They’ve got a shorter period in the market.

- The introduction cost is minimal as there are no research and development costs.

- These manufacturers that specialty in technology and the market space.

Original Equipment Manufacturers (OEM)

OEM is a type of manufacturing where a faucet factory produces and sells faucet products and other sanitary ware for another company. It’ll create products and put them under the company’s branding. More than that, it’ll design the products according to the specification of the company and then ship them to them.

In a nutshell, the buyer will provide the capital, trade secrets, and expertise. On the other hand, the manufacturer will make production and handle shipping logistics to distribution. It’s suitable for higher volumes of products, 2000-5000 MOQ, and wish to get a more customized service.

Here are some of the benefits of partnering with OEM:

- Products time on the time is fairly low

- Lower research and development costs

- Great chain buildup

- They know where to look out for, following up on the testing methodology.

Contract Manufacturer (CM)

Just like Original Equipment Manufacturers, Contract Manufacturers are open to assembling a thorough scope of products. It’s suitable for people trying to get a higher volume of products, like purchasing more than 10000 pieces. These manufacturers will allow you to control the quality and expenses. This is a better alternative to OEM.

Here are some of its benefits:

- Buyers must have the idea to pay and own the likely products.

- Better control of the entire situation regarding time, cost, and quality.

- Change from one particular manufacturer to the other is a standard cycle.

Trading Company (TC)

This company will associate with the buyer and the manufacturer of sanitary ware. You can think of them as mediators among discount providers and faucet manufacturers. They concentrate more on imports and fare rules by giving them guidelines and methodology.

The company manages many manufacturing factories. Trading companies build up their networks by distinguishing items. Here are some of the pros of partnering with them:

- They understand customer needs better and can sell suitable products for a particular region.

- Awesome customer service

- Promote products they supply.

Let’s look at the best faucet brands to partner with in 2023.

Top Seven Faucet Manufacturers in China

- INFAUCETS-Highest rated faucet manufacturer

- FAUCETU-Low cost faucet factory

- FOSILENT-Best faucet designs

- HUAYI-Luxury consumer brand

- HUIDA-Commercial design taps for wholesale

- SOLEX-Large scale selection for bathroom fixtures

- TORNEIRA-Best company for general homeowner

What makes these manufacturers stand out? Well, in how they’re producing their product. Let’s look at how they conduct their manufacturing processes.

Faucet Production Process: A Step-by-Step Guide

All faucet factories based in China ensure they meet quality control measures to produce superior products. We’ve compiled a step-by-step guide for faucet production in Kaiping City, China; let’s get straight to it without further ado.

Step One : Raw Materials

An alloy of copper, Brass, and zinc are the main two raw materials used to manufacture faucets. These raw materials have properties that can resist corrosion and calcification. Interestingly, components of faucets can also be made up of metals other than copper and zinc.

Step Two : Casting & Moulding

During the molding and casting, the core device is used to re-entrant angles and cavities in taps. The device brings out detailed features that can’t be integrated into various innovative designs, and afterward, it’s destroyed. Die casting will shape the body of the tap by melting the Brass at high temperatures and poured into molds of desired shapes.

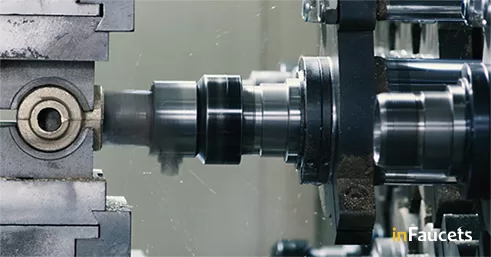

Step Three : Machining

At this computer-controlled stage, the surfaces of the die-casted tap are finished to a higher degree of efficiency and smoothness. The passage through which the water will pass will also go through this process. The process is done using a milling machine.

Step Four : Polishing

Polishing is essential to ensure the faucets have precise surface finishing. Such quality control measures ensure faucet products have an attractive sheen and shine. It entails a combination of machine-driven and manual processes, and after this is done, the faucet product is then taken to chrome plating.

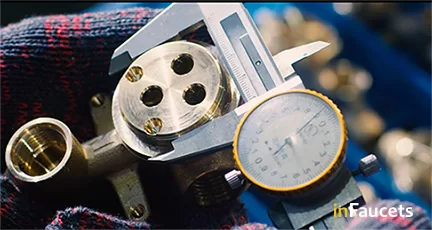

Step Five : Defect Checking

Before the faucet products go to electroplating, the faucets are checked manually to find defects like asymmetric curves and lines, geometrical errors, and polishing errors to ensure the next phase is efficient.

Step Six : Electroplating

The base coating will be applied to the product, then a thin electroplated chromium coating is applied. This layer is coated to ensure the product is corrosion-resistant and durable. It then goes into a computerized process to install a variety of components. The product is in the store for a short while before they’re sent to the assembly area.

Step Seven : Assembly Line

The phase involves manual and automated processes. It occurs in a rotary assembly machine to ensure this phase follows precise quality control measures. The nozzle is the first to get attached, followed by the cartridge and control levers.

Step Eight : Testing

Once assembled, the faucet products go through thorough testing on water and compressed air. The tests try to check for critical dimensions and durability. More importantly, sanitary ware needs to pass various environmental regulations.

Step Nine : Research and Development

A faucet factory will continue to ensure quality control measures by adding value to its products. This is done to meet the demand of the market’s ever-changing needs. Therefore, researching and developing new innovative product production methods is an ongoing process. It ensures the manufacturing process is effective.

Step Ten : Recycling

Each sanitary ware factory will have waste products after the manufacturing process. Therefore, this step ensures that waste materials like scrap metals are effectively recycled to dispose of them effectively.

The last step after production is usually transportation to the market once they’ve passed all tests.

Frequently Asked Questions

Where can I find faucet manufacturers in China?

Better known as the world’s factory, China has several reliable resources where you can easily connect with a reputable manufacturer. Here’s a list of them:

- Alibaba.com

- Trade shows

- Online trade sites, e.g., com

- Global manufacturing marketplace Com